- Home

composite moulding prototyping

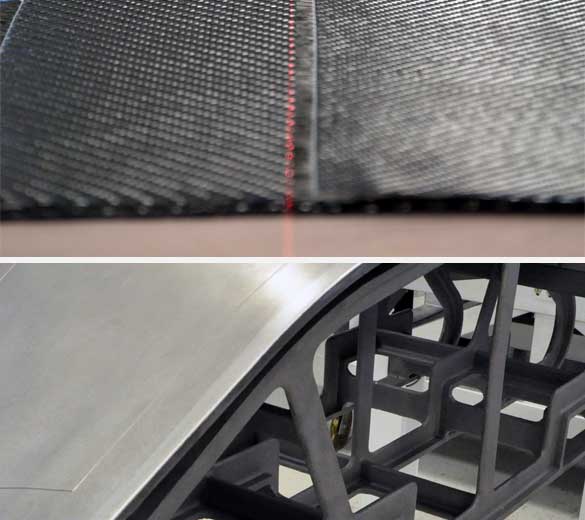

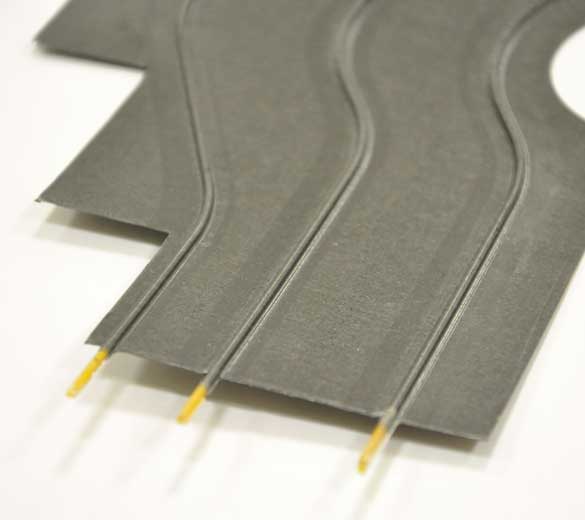

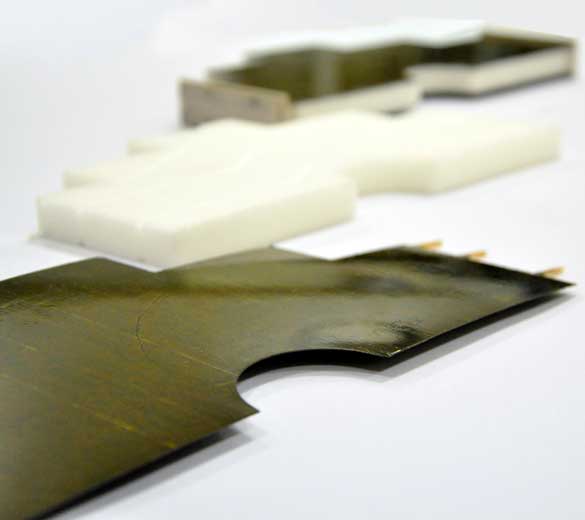

Composite moulding

ORATECH puts its expertise at your service in order to accompany you in the development of the composite molding of your parts and in the realization of prototype parts and small series, from the technical-economic study to the transfer of technologies within your structure. Thanks to its experience, ORATECH is ready to realize your parts in composite moulding of big dimensions.